First, the scope of application

1. Development of WDG water-dispersible granules in the pesticide industry.

2. Granules for granules in the pharmaceutical industry.

3. Chicken fine particles in the food industry.

4. Granules for granules in the diet industry.

5. Particles in the chemical industry.

Second, structural characteristics

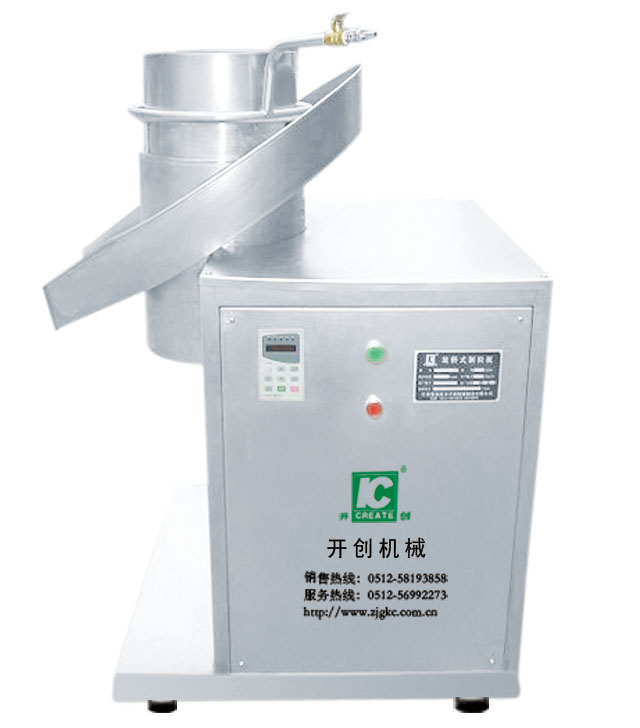

2 The upper part of the machine is a granulation structure. Its composition is mainly composed of a milling cutter, a mesh ring and a scraper. The contact parts of the mill and the mesh ring are made of 304 stainless steel. Acid and alkali resistant to ensure that materials are not contaminated.

2 The mechanical transmission components are placed inside the machine base to make the machine run smoothly and reduce noise. At the same time, the outer surface is closed with stainless steel plate for easy cleaning.

2 This machine is equipped with water cooling, air cooling and air sealing device, which has better granulation effect on high viscosity and heat sensitive materials.

2 It is not suitable for semi-solid, syrupy or strong viscous powders.

Third, the working principle and structure description

The granular device of the mechanism mainly comprises a mesh ring, a pressing material leaf and a large angle milling knife. The pressing material leaf rotates counterclockwise, the leaves are at an angle to enable the material to be pressed down into the milling cutter; the large angle milling knife rotates clockwise. The hexagonal spiral blade is provided with a large blade, and one end is closely attached to the sieve cylinder. When the cutter rotates, the large-angle spiral blade pushes the material toward the sieve cylinder wall, and the material is extruded from the sieve hole through the blade into particles. .

The motor in the motor base of the transmission drives the gear through the V-belt drive worm and worm gear reducer, and the gear shifts direction. At the same time, the inverter is equipped with stepless speed change, so that the cutter and the pressure roller are operated in opposite directions, and the operation is stable and the performance is reliable.

Third, technical parameters

model | power(kw) | Particle fineness(mm) | Yield(kg/h) | Milling knife size(mm) | Dimensions(mm) | weight(kg) |

| ZLB1-300 | 5.5-7.5 | Φ0.8-3 | 80-200 | 300 | 880×700×1300 | 400 |